EXCEPTIONNAL ENGINEERING

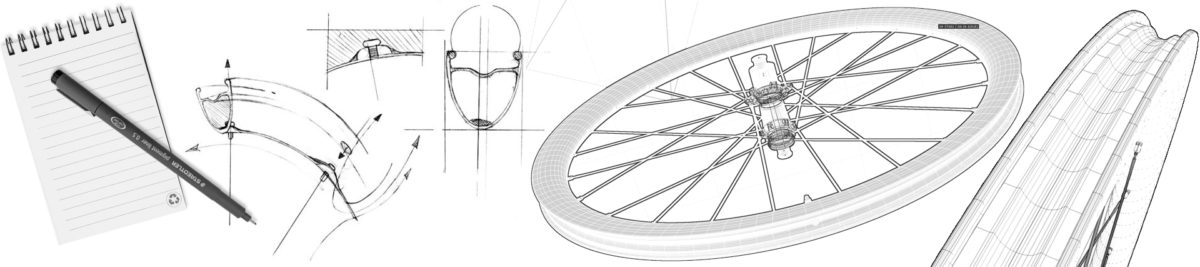

DESIGN

The blank sheet: an exhilarating and critical stage.

The product must push extremes, blending aesthetic harmony, ease of manufacturing, and geometric robustness.

This initial phase defines dimensions, traces curves, and locks in the geometry.

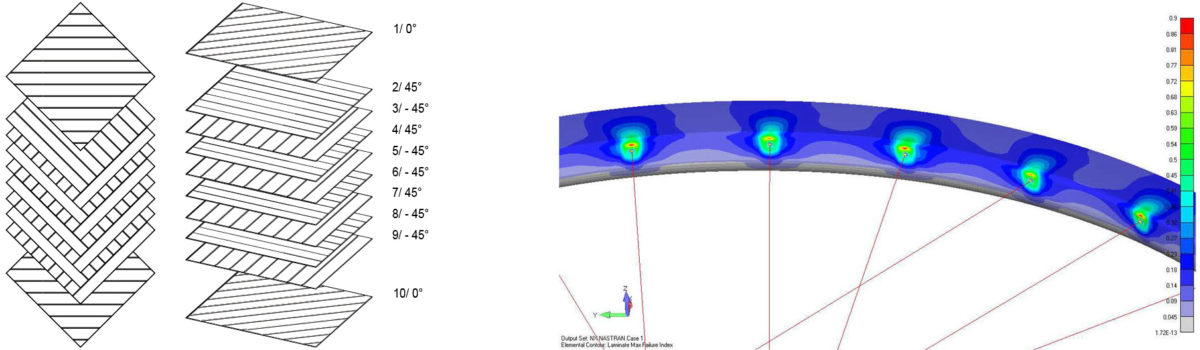

FINITE ELEMENT ANALYSIS

The foundational step.

The composite component, crafted with precision, is first modeled using computer-aided design software.

Stresses are evaluated through finite element analysis software, highlighting mechanically stressed areas where composite thicknesses and ply orientations must be adjusted.

LAYUP

A preliminary layup plan for pre-impregnated sandwich fabrics is prioritized, ensuring symmetrical deformation properties on both sides of the profile for maximum strength.

The layup plan is then refined, accounting for manufacturing constraints, application requirements, and results from static and dynamic tests.

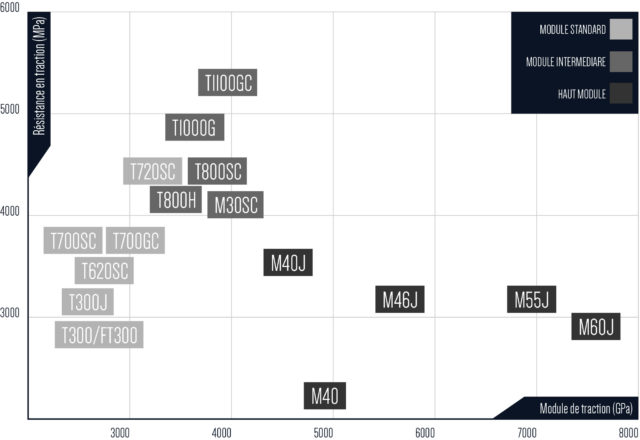

HYBRID MATERIALS

RAR rims, hybrid by nature, combine carefully selected Toray fibers to meet the demands of elite cycling.

Unidirectional T700 and T800 fibers provide optimal stiffness and strength, while 3K fabrics enhance impact resistance, ensuring durability across varied terrains.

For EXALT, M40J fibers increase lateral stiffness by 63% while reducing weight.

For AURA, high-modulus M46J fibers elevate performance to unmatched levels, minimizing deflections for superior force transfer.

Each rim zone, optimized via finite element analysis, benefits from precise layup with vacuum-applied epoxy resin, ensuring a uniform hollow structure.

This process, tailored to complex mold shapes, meets three key criteria: historic performance, controlled manufacturability, and secure supply despite aerospace and military industry constraints.

This advanced composite engineering shapes wheels with flawless performance and endurance.

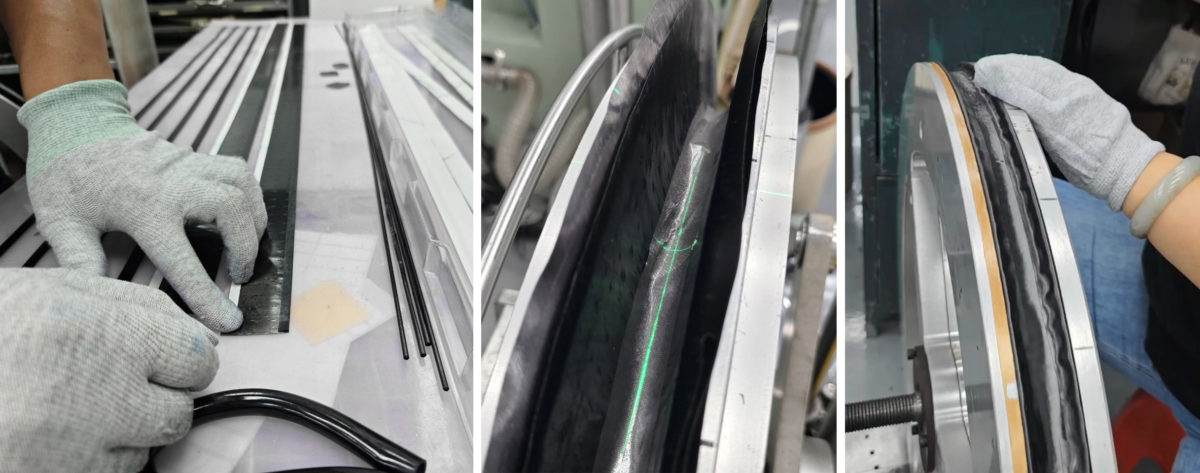

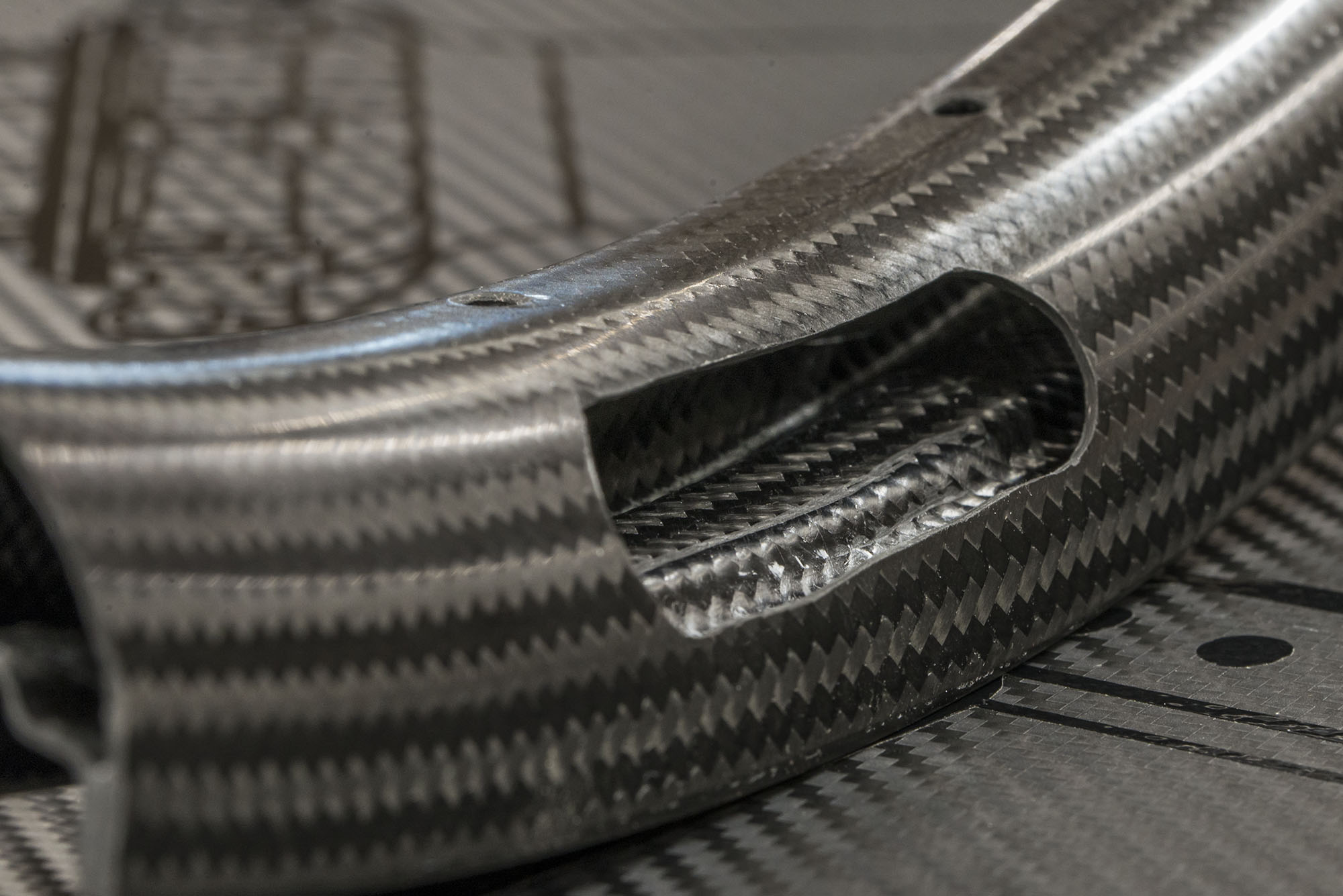

TOOLING & PRODUCTION

Blending artisanal expertise with cutting-edge technology, each RAR composite rim is born from tooling that enables efficient, high-quality production.

This tooling imparts unparalleled technical properties to the component.

Our steel tooling, machined for thermal stability and pressure resistance, ensures impeccable tolerances.

Production follows three precise stages: meticulous layup of pre-impregnated fabrics in complex molds, controlled-temperature curing in an oven, and careful demolding of the finished component.

An inflatable bladder, pressurized to 12 atmospheres, presses fibers and resin against mold walls, forming a uniform hollow structure, later removed to lighten the rim. For disc-brake rims, a resin with a 120°C glass transition temperature ensures optimal thermal stability. For rim-brake models, subject to frictional stress, a specialized 260°C resin, reinforced by post-curing, maintains composite fiber integrity.

Optimized through finite element analysis, composite thicknesses are refined to minimize weight in low-stress areas while reinforcing critical zones, ensuring maximum durability and responsiveness.

Each rim is drilled at precise angles to align spokes, ensuring seamless force transmission.

This advanced process, honed by our expertise, crafts composite rims that combine lightness, strength, and performance for exceptional rides on road or trail.

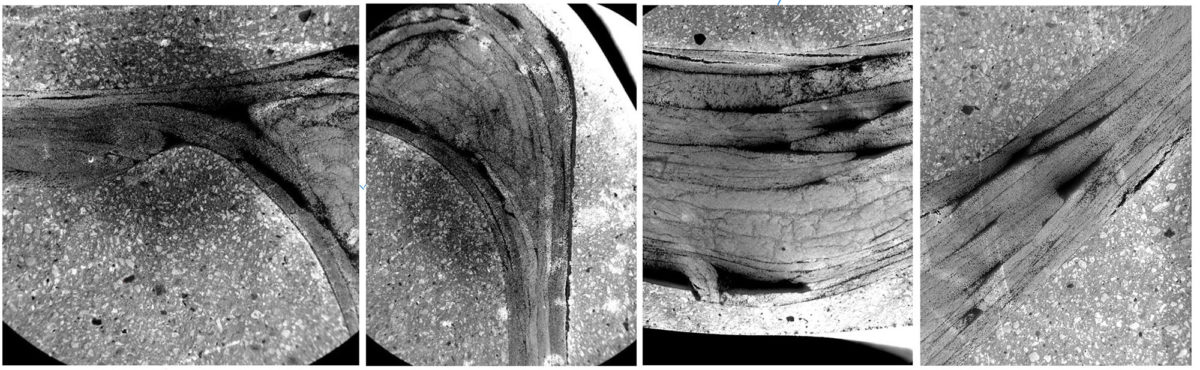

TESTING & QUALITY CONTROL

The production of RAR AURA, EXALT, and EVEN composite rims relies on a complex process where every technical challenge is identified and resolved through rigorous testing.

Angular and circular profiles, combined with pre-impregnated fabrics, can lead to defects such as inter-ply bubbles, ply slippage, left-right asymmetries, under- or over-thickness zones, or vibrational frequency variations across the circumference. These imperfections, detected through static and dynamic tests, are eliminated via scanning electron microscope analysis and iterative prototyping.

This uncompromising quality control ensures rims with mechanical uniformity and optimal efficiency, ready to withstand the demands of the toughest terrains with flawless durability.

Coupe de jante passée sous microscope à balayage électronique

Perçage de la jante carbone

0

0