RAR ESO Hubs

“CULTIVATING DISTINCTION”

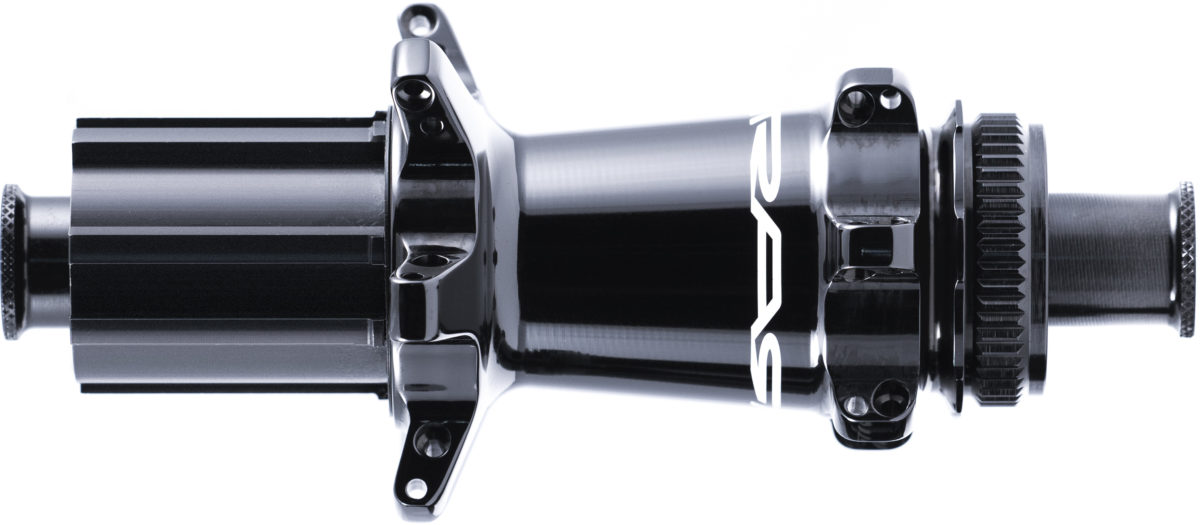

Conceived in 2012, RAR ESO hubs embody a high-end alternative: designed and manufactured entirely in France, they combine lightness, smoothness, and exceptional durability.

In a market saturated with replicas, we prioritize performance and resilience, the result of meticulous engineering.

We rejected easy solutions.

No off-the-shelf purchases.

No low-cost catalogs.

No recycled designs.

No simplistic pawl mechanisms.Our ESO hubs rely on continuous forms, 7075 T6 aluminum alloy, and precise machining for supreme reliability and lightness.

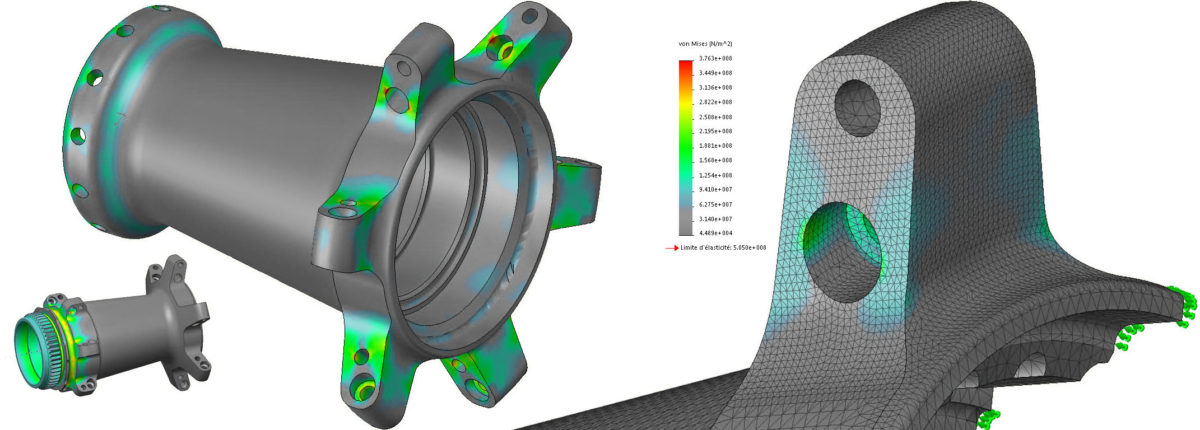

FINITE ELEMENT METHOD

Every superfluous cubic micrometer is eliminated through advanced finite element method (FEM) calculations.

Our simulations analyze extreme stresses—such as intense disc braking or spoke failure—to optimize dimensions.

Highly stressed areas, like spoke anchor points, receive targeted reinforcements, while less-stressed sections are machined to thicknesses sometimes below 1mm.

Fine meshing of critical zones, such as the flange under high spoke tension, ensures enhanced calculation precision, guaranteeing extraordinary strength.

For instance, simulating a spoke failure at the flange base reveals overload on the opposite anchor, which we counter with a reinforced design, ensuring flawless reliability even in the most critical scenarios.

The fine meshing of sensitive zones isolates a section of the component to enhance calculation accuracy.

RAR ESO disc-brake hubs leverage continuous forms, designed to balance supreme robustness with lightness.

While some competitors thicken walls to justify aesthetic machining, adding weight for an aggressive look, our approach prioritizes functional performance.

We select 7075 T6 aluminum alloy for its exceptional strength, machined with micrometric precision. This rigor allows precise sizing: critical areas, like spoke anchors under disc-brake stress, maintain optimal thickness for maximum durability, while less-stressed areas are reduced to sub-1mm thicknesses for optimal lightness.

This streamlined design, born of meticulous engineering, delivers unmatched mechanical efficiency, perfectly suited to the demands of EXALT wheels.

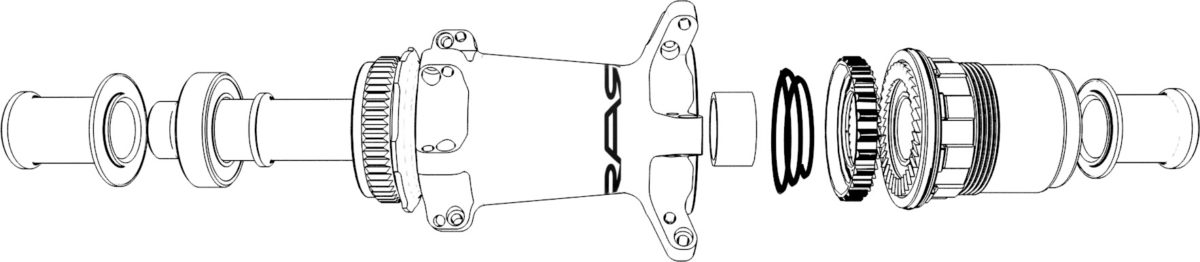

GEAR SYSTEM

We opt for opposing steel ratchet rings, distributing forces over a contact surface 20 times larger than standard pawl designs.

With a 10° engagement angle (36 teeth), optimized for road and gravel, they provide instant responsiveness and exceptional durability.

The fixed ring is integrated into the freewheel body, while the mobile ring slides into the hub, supported by a calibrated spring for quiet, smooth freewheeling.

Precision-machined steel ensures virtually infinite wear resistance, even under the high stresses of sprints or steep climbs.

GEOMETRIE

A decade of R&D has forged an unrivaled geometry for RAR ESO hubs.

By optimizing flange spacing and spoke anchor diameters, we create a superior lever arm, enhancing lateral stiffness and torque transmission. This approach, prioritizing mechanical precision over sheer mass, relies on micrometric machining by high-precision tools, allowing refined wall thicknesses while ensuring exceptional robustness.

-

Front: The asymmetrical design addresses braking torque stresses. Horizontal spoke anchors, more compact than vertical ones, lighten the hub while preserving robustness. The non-disc-side flange, designed for radial spoking, precisely balances spoke tensions, minimizing energy loss.

-

Rear: Featuring an inverted cone shape, this hub manages complex stresses from braking torque and high freewheel-side tensions. Vertical anchors maximize flange spacing for improved wheel stability.

Three distinct static tensions emerge: one on the non-freewheel side, and two on the cassette side, with the upper spoke (less tensioned, rearward-oriented) and lower spoke (more tensioned, forward-oriented).

In dynamic conditions, this configuration excels: the upper, pulling spoke increases tension during pedaling, while the lower, pushing spoke lightens, ensuring balance during power phases.

BEARINGS

Oversized for exemplary reliability, our hubs use ISO 61902 bearings (5/32″ balls) for critical areas: rear hub and front disc-side flange.

Less-stressed sections, like the non-disc-side front or certain small-diameter freewheels, use ISO 61802 bearings (3/32″ balls).

Assembled with high-performance SKF bearings (standard CN clearance, optimized low-friction grease), they ensure superior endurance.

Optional hybrid ceramic CyclingCeramic or SKF MTRX ultra-durable bearings are available for demanding competitors.

WEIGHT

Designed for ultimate performance, the ESO range is inherently ultra-light.

While weight reduction was not the sole priority, performance gains naturally stem from mass savings.

The hub pair weighs just 249g in its lightest configuration.

0

0