No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Télécharger votre configuration en PDF

TESTINGS - RESEARCH & DEVELOPMENT

Prior to releasing a new wheel on the market, we proceed to extensive testings to control and improve the global quality, the performance as well as the wheel reliability.

The "labs" and road testings help us find out where and which are the limit while using the wheels in extreme situations.

The results on these measurement benches guarantee the wheels' strength, security and conformity to the European standard. They also teach us many aspects of the wheel performance like lateral stiffness, extreme lateral load, rotational inertia and braking performance.

For any wheel of the range, RAR follows its main leitmotif: giving you the opportunity to ride reliable, durable, and ultra performant wheels. We give a lot of importance to the general wheel performance and its improvement over the years.

The RAR team includes several athletes of different levels. Some are pro riders, we have a couple of them riding at the highest amateur level, we also have triathletes as well as recreational racers, both for road/cyclo-cross and MTB. This diversity gives us many opportunities to collect an important feedback speeding up the wheel development.

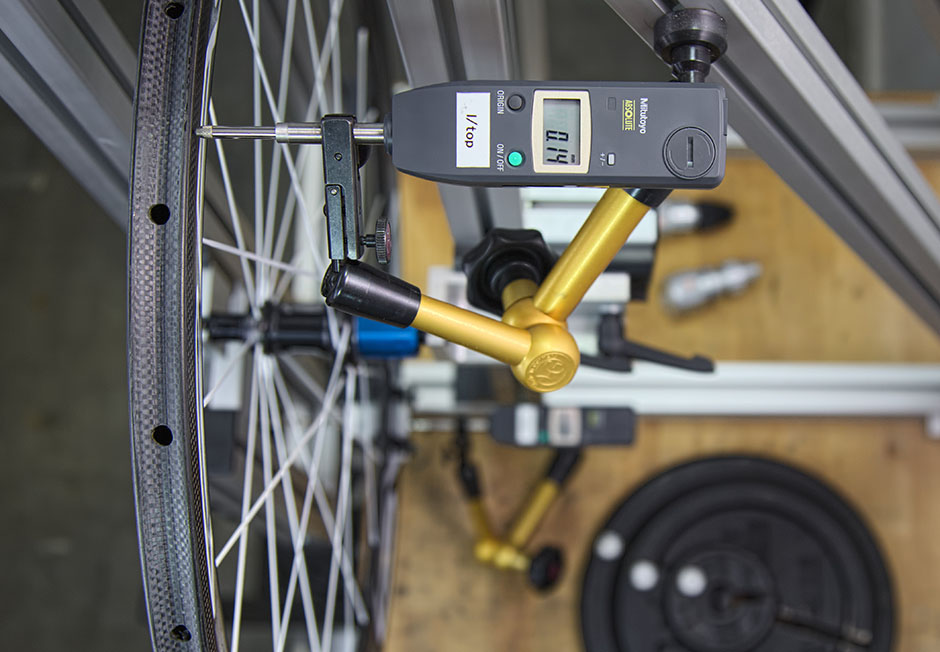

LATERAL STIFFNESS TESTING

The lateral stiffness test is about pulling on the rim in an accurate way to measure and control how much it deflects at different places of the rim.

These measurements are major to find out:

- how does the wheel react to accelerations

- the optimal rider weight and the wheels' limits

- the spokes endurance for a given configuration

With this strong experience in the wheel deflections, we can improve them over the years and adjust the different parameters:

- the spoke count, the spoke section and its angle from the hub

- the rim shape, rim material, the composite parts layup and fiber properties

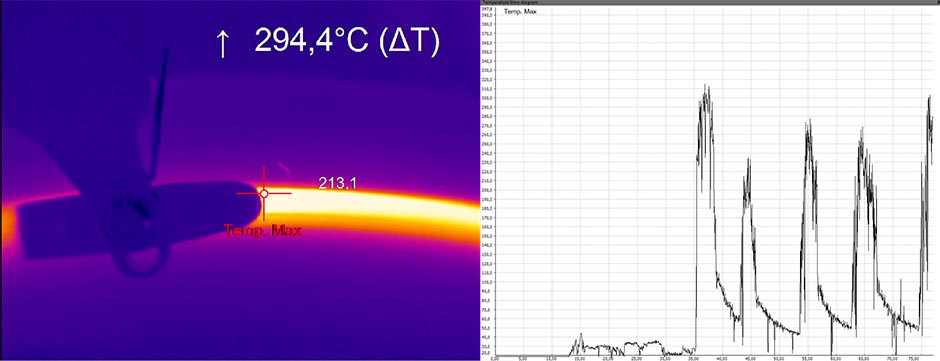

BRAKE PERFORMANCE TESTINGS

Carbon rims are the ultimate solution to reach the best performance: they are light and laterally stiff beside their aero properties. They really make sense when the whole rim: brake track and profile, is molded as one piece. The weight save and reliability gain is huge compared to the hybrid alloy/carbon solution.

These composites rims are made from successive woven or uni-directional carbon fibers, bonded together through an epoxy resin.

While braking, the brake pads enter in contact with the brake track, generating friction and temperature peaks up to 500°C in surface for the most extreme cases. It is of a major importance to control these temperature peaks as well as the resin capacity to handle the high amount of calories generated without exceeding its glass transition temperature. Above this temperature, the composite matrix enters in a new phase where it loses a part of its stiffness modulus, making it very sensitive to the 8 bars of the clincher...

The braking testings on composites fibers rims are crucial to make sure we deliver a safe and reliable product.

We proceed, prior to any new product announcement to several braking performance testings.

We find out the extreme limits and real braking conditions on the road:

- braking duration

- rest duration

- the pressure applied on the caliper and the rim

Then we reproduce these conditions in house with our own braking bench. We can also push the testing to different conditions:

- longer braking distances

- different resins

- different braking compounds

BEARING RESISTANCE TESTINGS

The bearing resistance of the hub is of a major importance for the wheel performance. Why making a super stiff and super light wheel, if the bearing waste a large part of the energy spent?

We use torque gauges to find out how much does the hub generate friction and we translate it into power loss.

These trials help us to optimize several significant parameters:

- the bearings the most adapted to our hubs

- the best setup to make the wheel rotation endless and the bearing last forever

- the perfect amount of lateral play to make the hub as efficient as possible when it is clamped into the dropouts.