No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Télécharger votre configuration en PDF

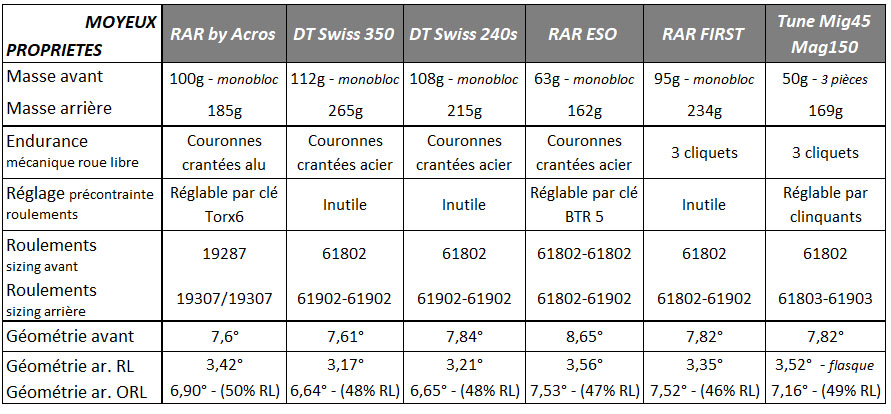

HUBS - Rim brake comparative

10,000 wheels. 100.000.000km This is the distance that we have on our productions and on the designs of the existing components on the market.

Our experience in wheel assembly and hub adjustment has built our reputation. 100% of the parts we use have been tried and tested for many years. We reject risky designs and technologies that have failed to meet our quality and endurance requirements.

Today, in addition to this selection of the most accomplished hubs, we develop our own parts, based on this strong experience.

RAR ESO hubs benefit from the expertise acquired through this diversity, they are our flagship.

The RAR FIRST hubs, offer a visual cut close to the ESO, share some technical solutions, and benefit from more accessible manufacturing methods.

We have chosen Tune and Acros manufacturing hubs for their complementary qualities, their common reliability and the availability of spare parts. DT Swiss hubs are also available.

Straight pull hub comparative

Straight pull: spoke head hidden into the hub shell, the nipple is accessible near the rim

The hub is the support of the wheel structure. Its internal and external sizing has a direct influence on the dynamic properties of the wheel. Each of these properties has an impact on the short, medium or long term operation of the wheel.

Weight

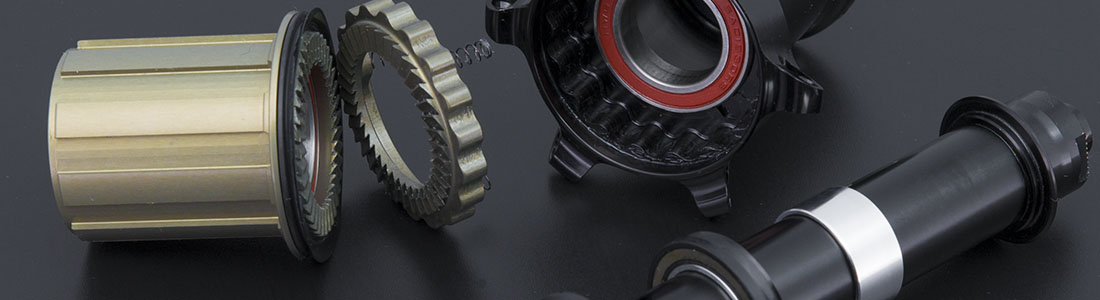

Freewheel mechanic endurance

This is an important criterion for the endurance of the hub. There are several systems for transferring the pedaling torque from the freewheel to the hub body.

The light historical system is the pawl system: 2 or 3 or even 4 teeth are in contact with a ring gear. This is the solution used on the RAR by Tune hubs or the Tune Mig45/Mag150 with 3 pawls. This system is reliable and offers an endurance of the wearing parts (aluminium freewheel body) between 15.000 and 30.000km depending on the power of the cyclinst even if we have already carried out a maintenance on a 2010 RAR by Tune hub with more than 120.000km!

The second solution we have chosen for this criterion is the double ratchet in opposition. This is originally the Hügi system. This system drastically increases the contact area between the transmission parts and thus also the endurance of the system.

Opposing ring ratchets can be made of aluminium, for a service life between 20,000 and 40,000km, or steel for a much higher endurance: expect at least 60,000km and probably more than 200,000km in the best cases.

Pre-load bearing system

Some hubs (RAR by Tune) can be adjusted with washers to wedge the axle from left to right against the bearings. It's archaic, the original adjustment is tedious but final if it is correctly done taking into account the compression force of the quick release.

Other hubs benefit from an adjustment by hex keys inserted on each side of the axle (RAR ESO), or an adjustment by a worm screw (RAR by Acros). Finally the DT Swiss or RAR FIRST hubs do not allow any adjustment, their cap system with seal avoids compressing the bearings while closing the wheel quick release.

Front hub geometry

The front hubs all have a geometry good enough to maintain the rim position. However, between good and excellent geometry, differences are noticeable in lateral stiffness, vertical comfort and steering precision.

In concrete terms, the most accomplished geometry of a front-road hub will be the one that will offer:

1. the greatest distance between the points of attachment of the spokes (the flanges): the rim will have an important right/left support that limits its movements.

2. larger diameter flanges: they will increase the lateral stiffness of the wheel by reducing the size of the spokes.

From these two parameters we can deduce the angle the spokes take at the hub exit: this is the "umbrella". The more it is open, the more the rim is supported laterally by the spoking, and the better it will behave.

For each of these two points, there are parameters to limit the extremes.

1. The longer the body, the longer the starting bar to be machined and therefore more expensive in material and machining. The finished product is then heavier too. Some manufacturers then pretend to machine 3 different parts assembled together: the mass, rigidity and endurance of the elements are then reduced compared to a monobloc body.

2. In the same vein, the larger the diameter of the flanges, the larger the diameter of the starting bar. The finished product is therefore heavier, more expensive in raw material and machining.

It is therefore a question of positioning the slider in the right place knowing that the width of the hub will have a greater impact on the wheel's performance than its diameter.

Our front RAR ESO hub benefits from the best geometry on the market: the lateral stiffness of the wheel and its comfort are at the maximum, while keeping a monobloc body synonymous with reliability and robustness.

Rear hub geometry

The geometry of the rear hub is of crucial importance in the wheel efficiency. Design efforts reduce flange and freewheel encumbrance to improve wheel efficiency.

The rear hub will benefit, like the front one, from the flange spacing and flange diameter. However, the cassette body alters this situation. It encumbers the hub by almost 40mm, in addition to its internal mechanics, and seriously pushes the freewheel flange towards the inside of the wheel.

Several modifications on the ideal design of the front hub are generated:

1. The distance from hub center to the drive side flange is dramatically reduced and becomes critical for the geometry.

2. The distance between the flanges cannot be increased excessively since the spoke tension on the non drive side spokes will depend on the position of this flange.

Very concretely, the most accomplished geometry of a rear hub will be the one that offers the best distance (bracing angle) on the freewheel side. The combination of the spokes hooking diameter and the distance to the center of the wheel is crucial. It is on this side that the left/right tension ratio of a rear wheel will be born.

On the opposite side of the cassette, the positioning is important but secondary.

Placed very close to the center of the wheel, it will generate close left to right spokes tensions, but the wheel will benefit from a low lateral stiffness.

Conversely, placed very far from the center, the lateral stiffness will be the better but the left/right spoke tension ratio and wheel reliability will be affected.

Once again, it's a matter of compromise. Knowing that the best situation is to push the drive side flange as much as possible from hub center so you can also move the non-drive flange away from the center without depreciating the spoke tensions and increasing wheel stability.

We pushed the RAR ESO freewheel side flange 17.7mm from the center of the wheel. This limit value, due to the high derailleur top adjustment and the design difficulties, allows us to get an incomparable bracing angle of 3.56°.

It also allows us a very favorable angle on the non-drive side of the wheel with 7.53°, meaning an excellent lateral stiffness, while maintaining a 47% tension balance right/left for the required reliability.

Only the RAR by Tune or Tune Mag150 hubs with 3.52° are close to the ESO because of their traditional cassette flange for J-bent spokes that encumbers less the spacing (in Tune straight pull design the angle would drop under 3.3°). The traditionnal J-bent spoke design doesn't allow to aim the spokes tangentially to the hub. The energy transfer of the straight pull design is better because the spoke direction is very close to the hub tangent.